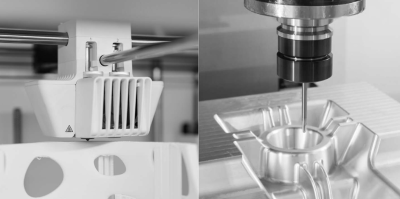

CNC machining and 3D printing are common processing methods in industrial manufacturing. Each method offers distinct advantages and benefits, and both offer significant benefits. CNC machining is subtractive manufacturing, while 3D printing is additive manufacturing.

Before choosing a manufacturing method, you must carefully consider several factors, including the scale of production, the product's development history, timelines, and overall budget.

Criteria for Selecting a Production Method

In the industrial sector, when creating prototypes, we typically face two production methods: 3D printing and CNC machining.

However, which method best meets your specific needs? This requires a deep understanding of the unique capabilities of each technology. For small-batch, budget-constrained production, 3D printing is ideal; CNC machining is suitable for large-volume, high-volume production. For production runs exceeding 100 units, technologies like vacuum injection molding may be recommended.

For prototypes requiring high functionality and subject to significant stress or strain, CNC machining is more suitable, as it offers higher dimensional accuracy and surface finish. While 3D printing is flexible, it generally lacks the strength and durability of CNC machining. The choice of technology also depends on production volume and budget.

What is subtractive manufacturing?

Subtractive manufacturing refers to the process of reducing material during CNC machining to achieve the desired result. The most common subtractive manufacturing method is computer numerical control (CNC) machining. The history of subtractive manufacturing dates back to the 1940s, when engineer John T. Parsons developed the first CNC machine to achieve highly complex, repeatable, and precise production designs.

Subtractive manufacturing involves gradually removing materials such as metal, plastic, and wood through cutting, drilling, and grinding to complete the manufacturing process. While these processes can be completed manually, manual machining, measurement, and reduction inevitably introduce errors. Furthermore, the time and labor costs involved in production are high, so industrial manufacturing generally relies on CNC machining. Other common subtractive manufacturing methods include laser cutting, water jet cutting, electrical discharge machining, and plasma cutting, which are primarily used for flat surface machining.

In CNC machining, the production process is numerically controlled by computers. This involves designing products using CAD software and manipulating CNC machines using CAM software to produce geometric shapes.

CNC machining has been around for over 80 years, and with advancements in technology, its application has expanded significantly. Because the machining process requires reducing raw materials to complete the product, while the past decade has seen a constant evolution in machining methods, many new approaches have emerged in industrial manufacturing, but subtractive manufacturing remains the most common and widely used.

Advantages of the 3D printing process:

- It eliminates the need for molds, enabling the production of complex geometries without compromising time or cost. It allows users to quickly deliver small batches of parts and flexibly adapt to design changes.

- It supports parallel part processing, saving time. Users can produce multiple parts within a single project, multiple versions of a single part, or multiple parts for different projects.

- It eliminates the need for multiple setups to produce parts, and requires no operator supervision or intervention. Once a job is started, the machine runs continuously until the part is complete.

Quality Characteristics

- Materials. The 3D printing process as a whole can handle a wide range of material categories, but each technology can only process a single material category, encompassing a small number of materials within that category. CNC can process a wide range of materials, and within each category, there are many options, limited only by the material's machinability.

- Material Properties. After CNC machining, the mechanical properties of the resulting prototype are nearly identical to those of the original material. After 3D printing, the prototype's properties are similar to those of the original material. It's also important to consider that 3D-printed parts are often anisotropic due to the layered nature of the process.

- CNC processes have tighter tolerances.

- CNC produces a smoother surface finish.